The Innovative Impact of Automatic Label Counters on Business Efficiency

In today's competitive business landscape, companies are constantly seeking ways to improve their operational efficiency and reduce costs. One remarkable advancement that has significantly contributed to this goal is the automatic label counter. This innovative device streamlines the labeling process, enhances accuracy, and ultimately drives productivity in various industries, particularly in printing services and electronics.

Understanding the Automatic Label Counter

An automatic label counter is a specialized device designed to count, control, and manage labels with impeccable precision. These machines are integrated with advanced technologies that allow for quick and accurate counting, thus reducing the likelihood of errors commonly associated with manual counting processes. For businesses involved in distributing products that require labeling, the adoption of such technology is a game-changer.

The Benefits of Using Automatic Label Counters

Investing in an automatic label counter offers numerous advantages for businesses. Here are some key benefits:

- Increased Accuracy: Automatic label counters significantly minimize human error during the counting process, ensuring that each label is counted accurately.

- Enhanced Productivity: By automating the counting process, businesses can reduce the time needed for label preparation, allowing staff to focus on other critical tasks.

- Cost-Effective: Although there is an initial investment, the long-term savings achieved through reduced labor costs and decreased waste can be substantial.

- Versatile Applications: These counters can be utilized across various sectors, including manufacturing, logistics, retail, and more, making them a universal tool for counting needs.

- Improved Workflow: The integration of automatic labeling counters into existing systems can significantly streamline workflows, reducing bottlenecks and enhancing overall efficiency.

How Automatic Label Counters Work

Understanding the mechanics behind an automatic label counter helps businesses appreciate its value. These devices typically function through the following steps:

- Label Feeding: Labels are fed into the machine either from a roll or stacked flat. The design allows for various label types and sizes to be accommodated.

- Counting Mechanism: Using optical sensors or mechanical counting systems, the machine detects and counts each label as it passes through, ensuring no label is overlooked.

- Batch Control: Users can program the machine to count to a specific number, after which the device can alert the operator or automatically stop, ensuring precise batch production.

- Display and Reporting: Most automatic label counters come equipped with user-friendly interfaces that display real-time counts and can provide detailed reports on operational efficiency.

Choosing the Right Automatic Label Counter for Your Business

When selecting an automatic label counter, it is crucial to consider several factors to ensure you choose a model that meets your business needs:

- Label Size and Type: Ensure that the model can handle the dimensions and material of the labels you use.

- Counting Speed: Depending on the volume of labels you process, choose a counter that offers the speed you require.

- Ease of Use: A user-friendly interface will make the adoption process smoother and training easier for your employees.

- Integration Ability: Look for counters that can be easily integrated into your existing printing and labeling systems.

- Customer Support and Warranty: Reliable customer support and a good warranty can make a significant difference in maintaining your machine's functionality.

Real-World Applications of Automatic Label Counters

The versatility of the automatic label counter makes it a valuable asset in a variety of settings. Some notable applications include:

1. Manufacturing Industry

In manufacturing, precise labeling is crucial for inventory management and compliance. Automatic label counters ensure that each product is accurately labeled, facilitating tracking and quality control.

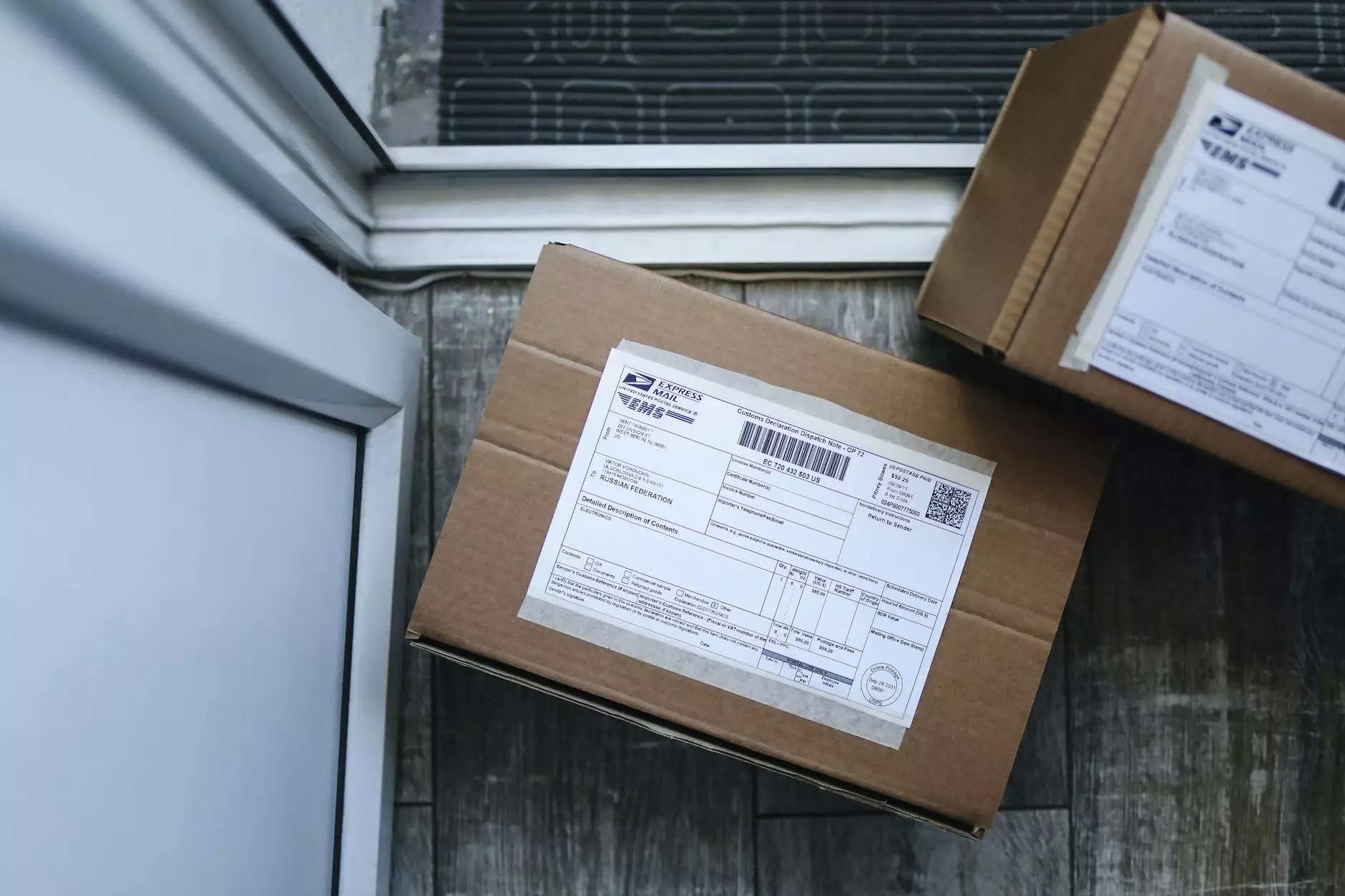

2. Logistics and Shipping

For logistics companies, the correct labeling of parcels is paramount. Automatic label counters streamline the sorting and shipping process, ensuring that packages reach their destinations without mislabeling.

3. Retail Sector

Retailers can utilize these counters during stock-taking and inventory management processes, enhancing efficiency and accuracy when managing large volumes of labels.

4. Pharmaceuticals and Food Industries

In highly regulated industries like pharmaceuticals and food production, maintaining labeling accuracy is not just a matter of efficiency; it’s a matter of compliance. Automatic label counters help meet regulatory standards by ensuring accurate labeling.

5. Electronics Manufacturing

In electronics, precision is key for product identification. Automatic label counters can easily count and ensure the correct labeling of components that require detailed identification for assembly and sale.

The Future of Automatic Label Counters

As technology continues to evolve, the future of automatic label counters looks promising. Here are some trends to watch for:

- Integration with IoT: The Internet of Things (IoT) is poised to revolutionize how label counting and management systems operate, allowing for real-time tracking and data sharing.

- Artificial Intelligence: AI could enable more sophisticated counting methods, predictive analysis, and anomaly detection to further enhance operational efficiencies.

- Increased Customization: Future models may allow for greater customization based on specific business needs, providing tailored solutions to a wider range of users.

- Sustainability Features: As companies become increasingly environmentally conscious, label counters that minimize waste and utilize sustainable materials will likely become more popular.

Conclusion

In a world where efficiency and accuracy are paramount, automatic label counters stand out as a transformative technology for businesses. By adopting these devices, companies not only enhance their productivity but also ensure accuracy in their labeling processes. Whether in manufacturing, logistics, retail, or food production, the benefits are undeniable.

As businesses like DuraFast Label Company continue to innovate and provide high-quality printing services and electronic solutions, embracing tools such as the automatic label counter will be essential for those looking to stay ahead in their industries. The time to invest in efficiency is now, and the future is bright for those who choose to automate their labeling processes.